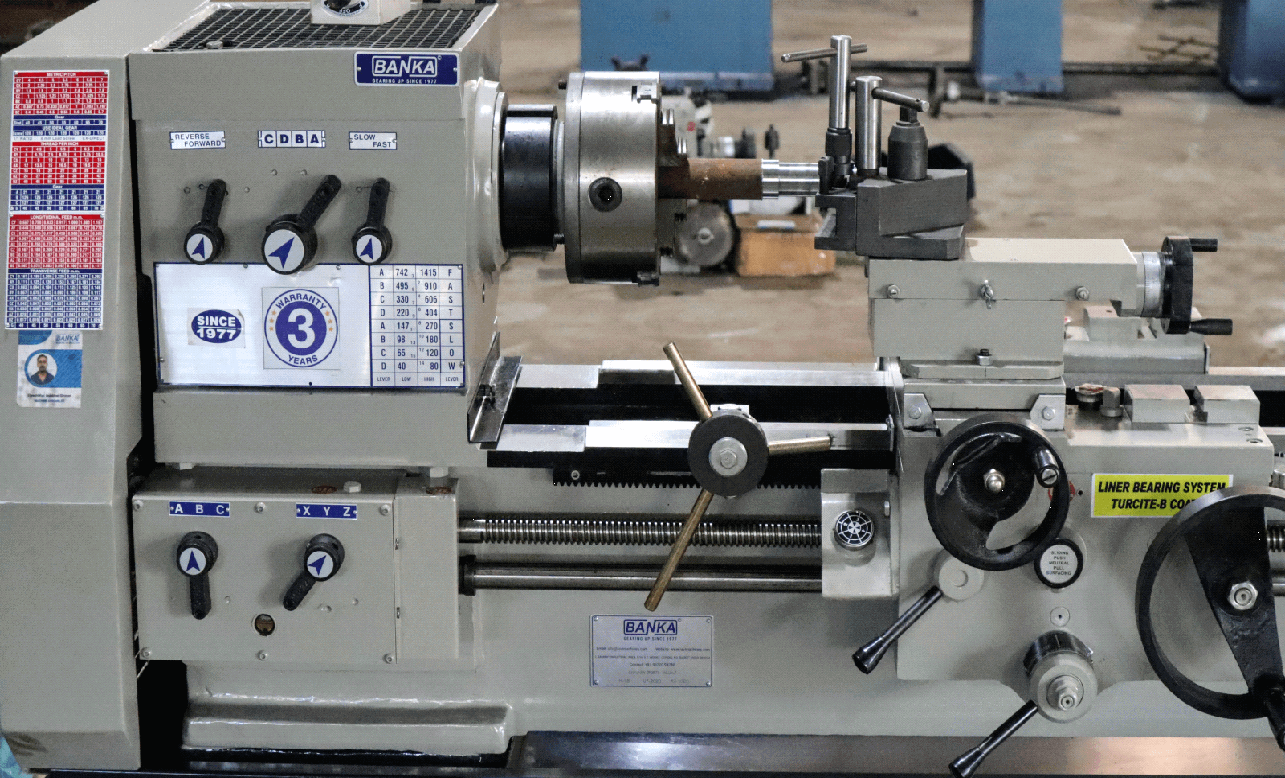

लेथ में वाइब्रेशन आने के कारण जाने – Reasons for Lathe Vibration or Ruttle

1.लेथ मशीन में वाइब्रेशन को कैसे चेक

Checking vibration in your Lathe Machine is not a big deal. You can check the vibration with your Mobile Phone with some easy steps

- First, download the VIBRATION METER Android app from Google Play Store.

- Open the App, put it once on the Headstock of your machine and then on the Tailstock of the Machine.

- If it shows the permissible RMS then it’s fine otherwise it will cause vibration.

- Check machines in two conditions: Load Condition– Condition in which jaw is inserted, here the vibration should not be more than 2.5 RMS. Another is the No-Load condition – In this condition, the machine should get started under 1.5 RMS.

2. लेथ मशीन में वाइब्रेशन किसकी वजह से आता है ? What causes the vibration in the #Lathe machine?

Some invade reasons can cause vibration in you machines like –

- RMS more than 2.5 causes vibration in the machine.

- Blunt tool, mismatched material of tool, and the difference of the speed can cause vibration.

3. खराद मशीन में कंपन कब होता है? उसे रोकने के लिया क्या करना चा

- There should be no debris in the Revolving center. The revolving center has some bearings in it. If Backless has occurred then it will cause vibration in old Machines.

- You should be careful about the cleaning of the machine by your operator to prevent vibration.

- The unbalanced copper filling in the rotor like in Submersible pumps can cause vibration at high RPM.

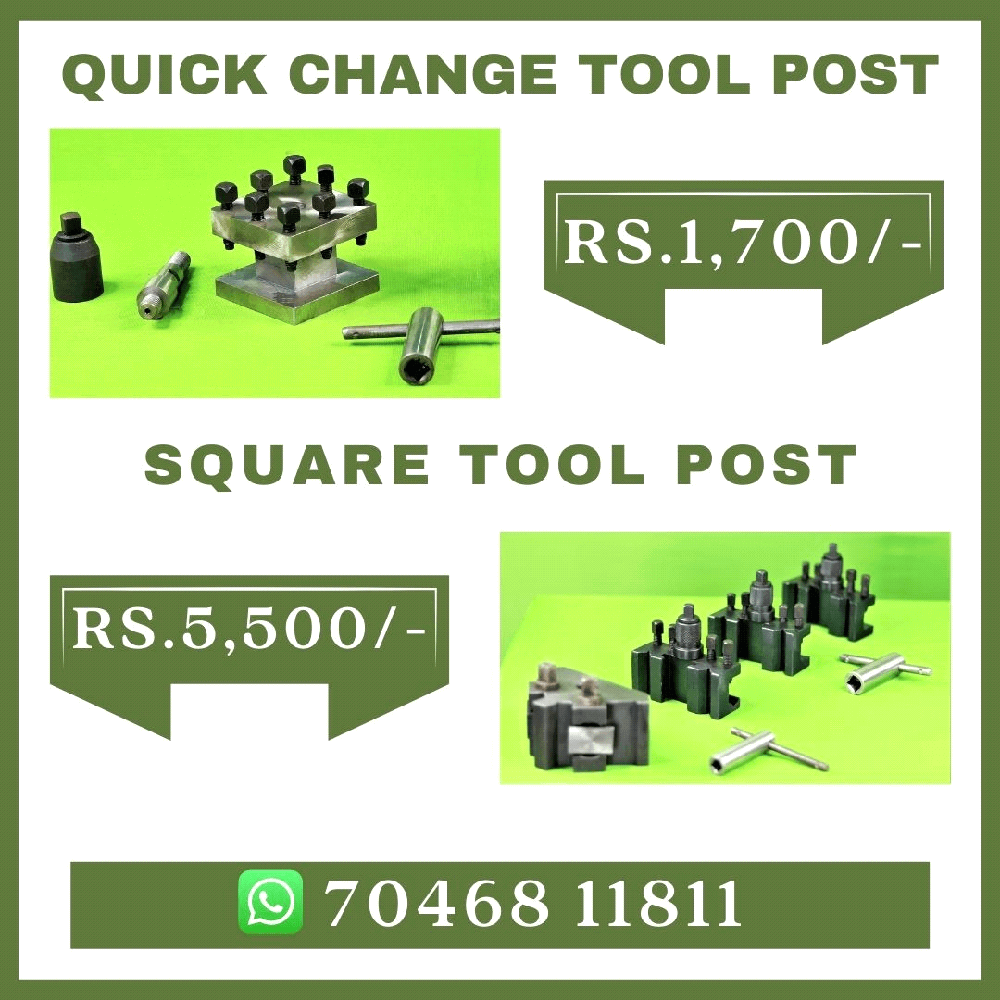

- There are two tool posts, a quick change tool post, and a square tool post. Square tool posts have more power due to the absence of joints. But in the quick change tool post vibration could occur as it has two parts: a holder and a post and there should be no garbage between them. This will resist vibration in the jaw.

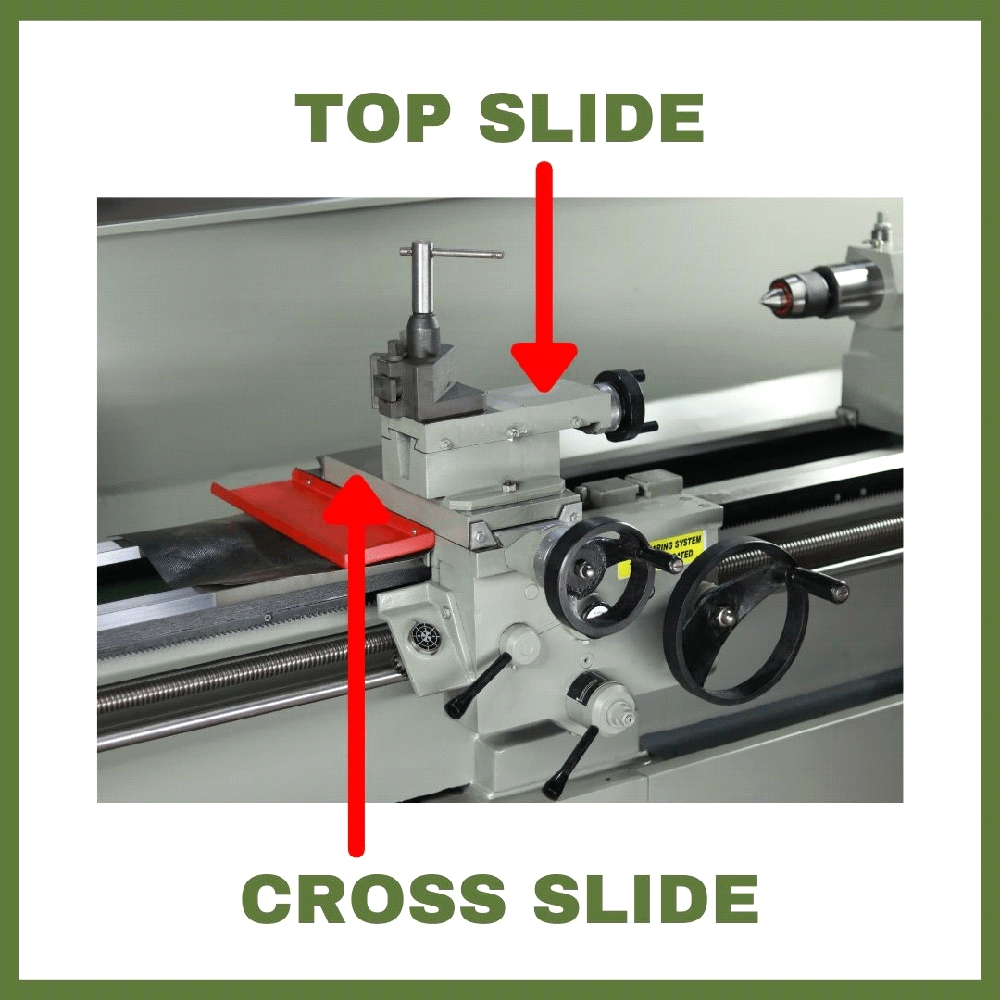

- The bolts of the Top slide and the cross slide should also be tightened. This will prevent vibration.

- The machine’s Legs should be leveled. Leveled legs will protect your machines from vibration.

4. लेथ मशीन में वाइब्रेशन कितना होना

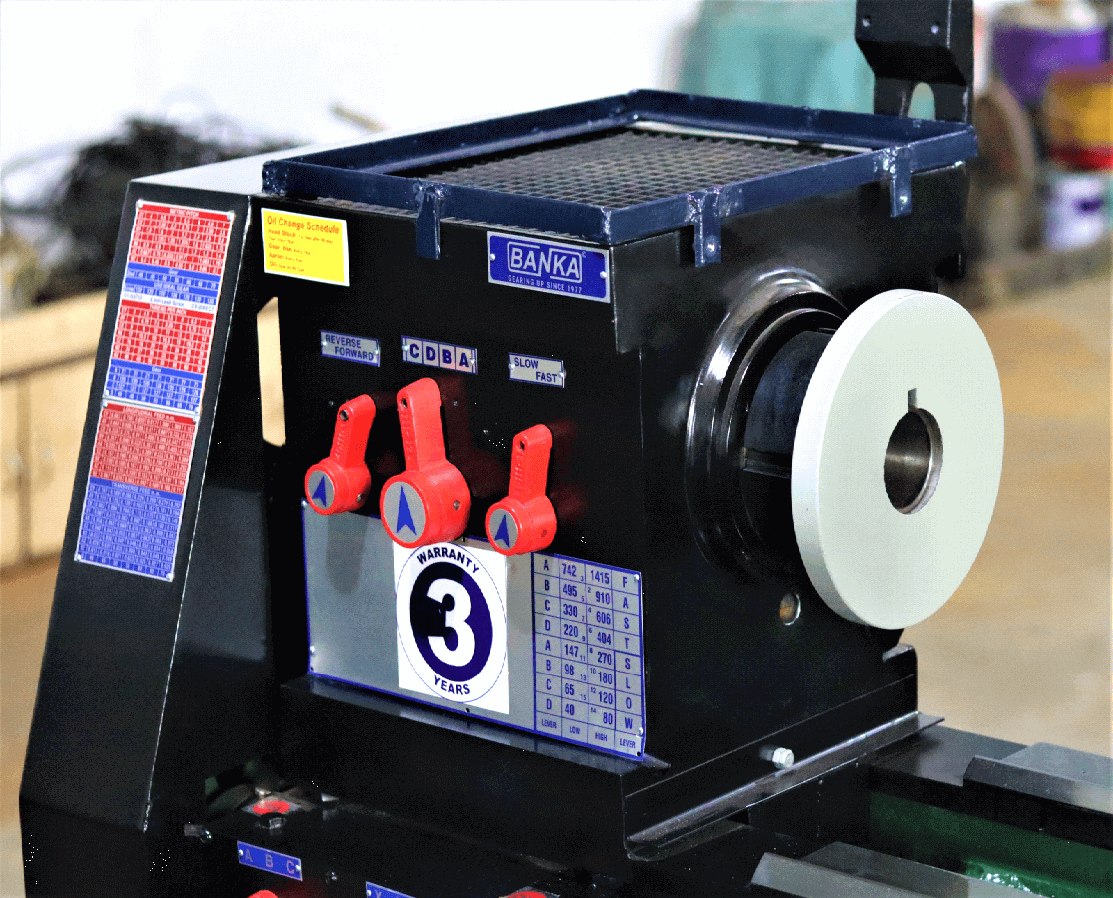

The vibration should be less than 2.5 RMS. Banka tries to keep RMS less than 1.5 RMSwhile starting the machine at no-load condition.

5. लेथ मशीन में कंपन और आरपीएम चेक कर

Why is it important to check the vibration and RPM in the lathe machine?

The machine’s jaw should not overhang. In this case, when your jaw will rotate with speed it will cause vibration. And in that case, you have to lower the RPM to prevent vibration. That’s why checking RPM is important.

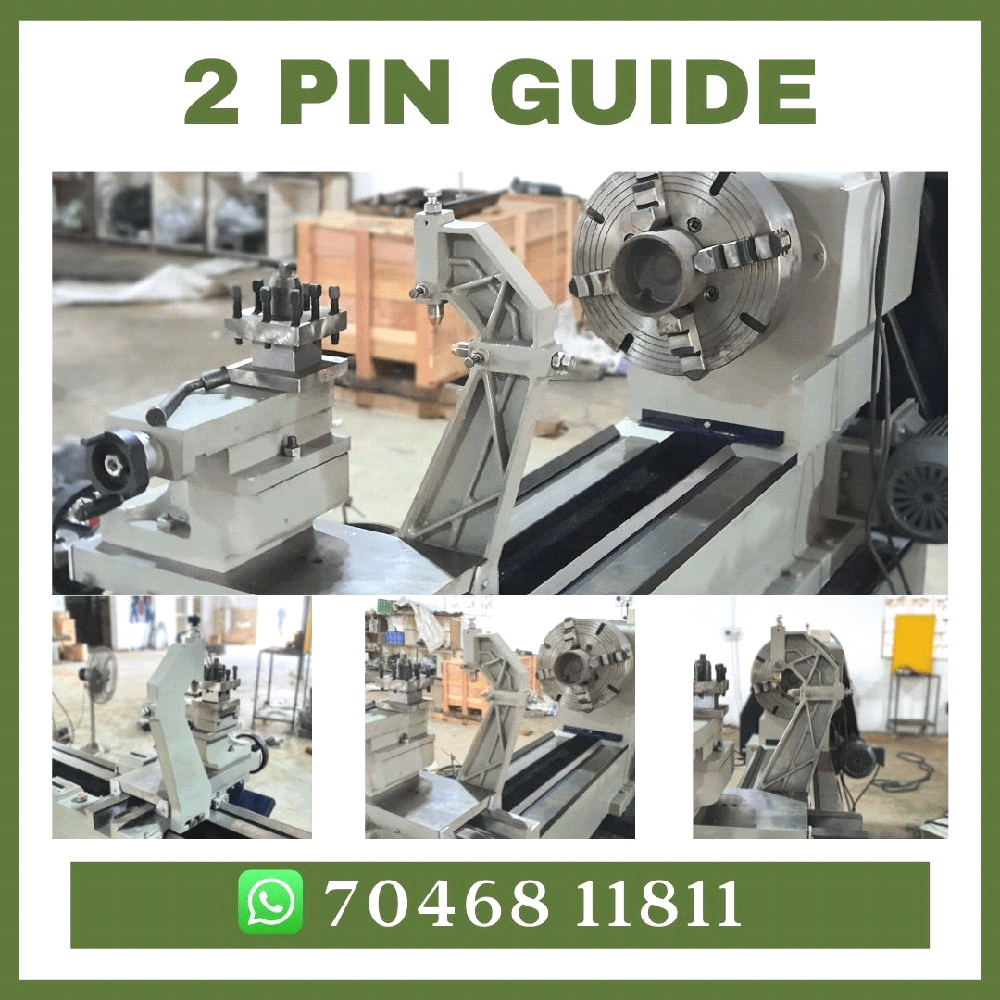

6. २ पिन गाइड लगाने से क्या फायदा

What are the benefits of installing a 2 pin guide?

When the machine does turning for thin rods the tool applies pressure to the jaw which pushes it backward, 2 Pin Guide will resist its backward moment and will finish the cutting earlier without vibration.

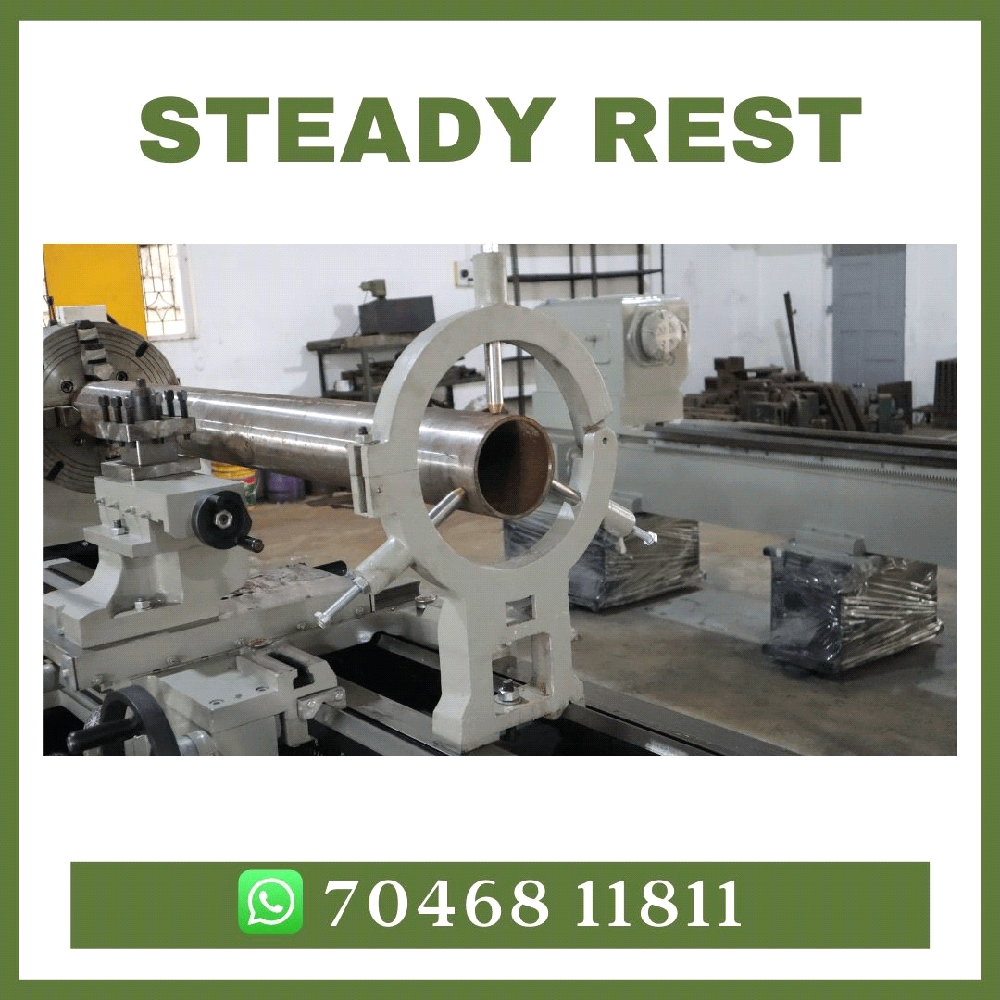

7.लम्बे जॉब के लिए स्टेडी रेस्

Why is it necessary to apply steady rest for long jobs?

Vibration is problematic for any turning, but it is particularly problematic when turning long spindles, or hollowing out deep vessels. To reduce vibration, a steady rest provides needed support. Typically, steady rests are selected to provide support for longer cuts.

Lathe Machine Manufacturer