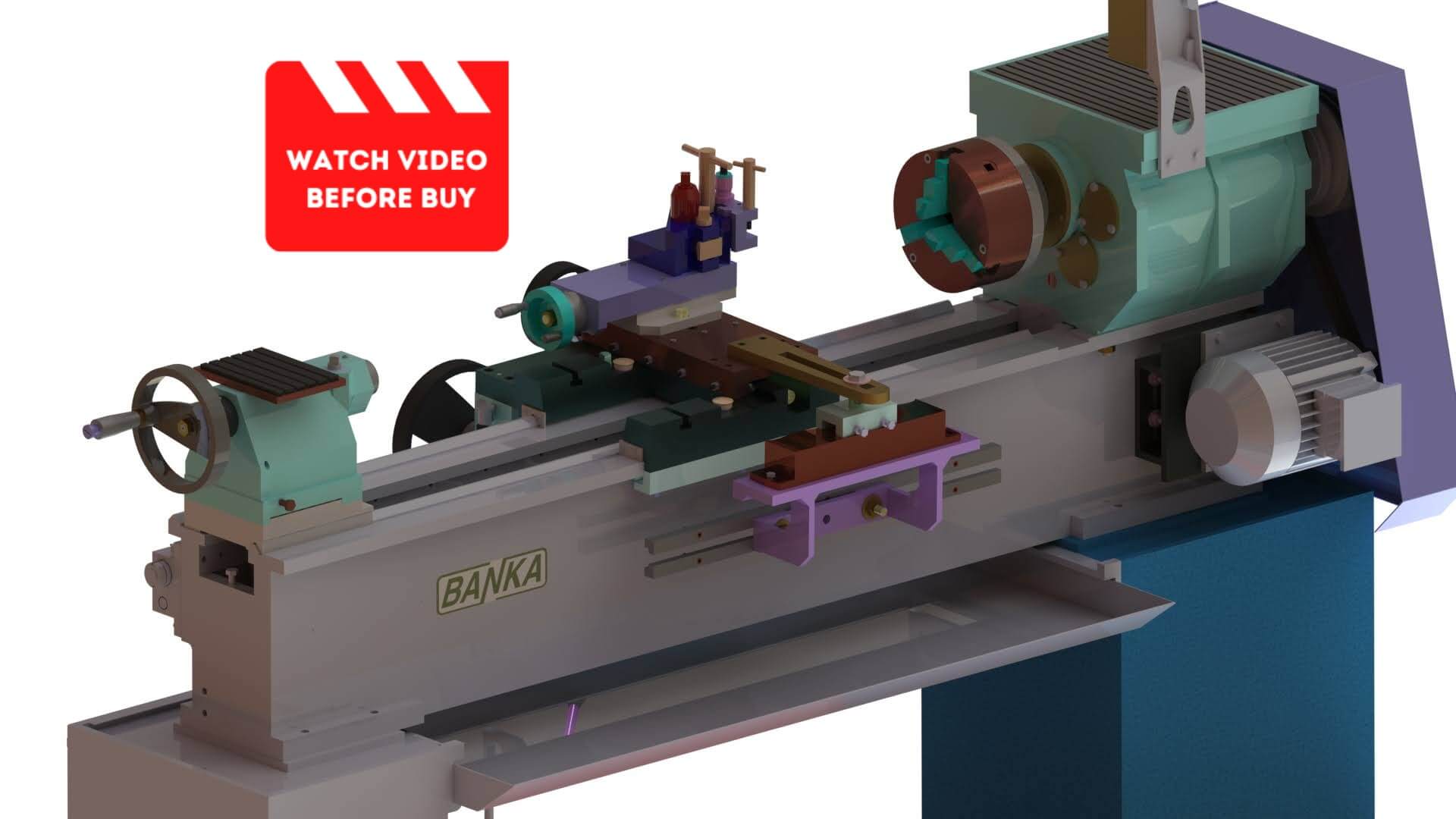

Taper Turning Attachment For Lathe Machine

₹8,900 ₹7,500

- Tapers are classified by American Standards Association as self-holding tapers and steep or self-releasing tapers.

- Self-holding has been applied to the smaller tapers-like Morse and the Brown & Sharpe- because, where the angle of the taper is only 2 or 3 degrees.

- The shank of a tool is so firmly seated in its socket that there is considerable frictional resistance to any force tending to turn or rotate the tool relative to the socket.

- The term “self–holding” is used to distinguish relatively small tapers from the larger or self-releasing tapers.

Taper Turning Attachment

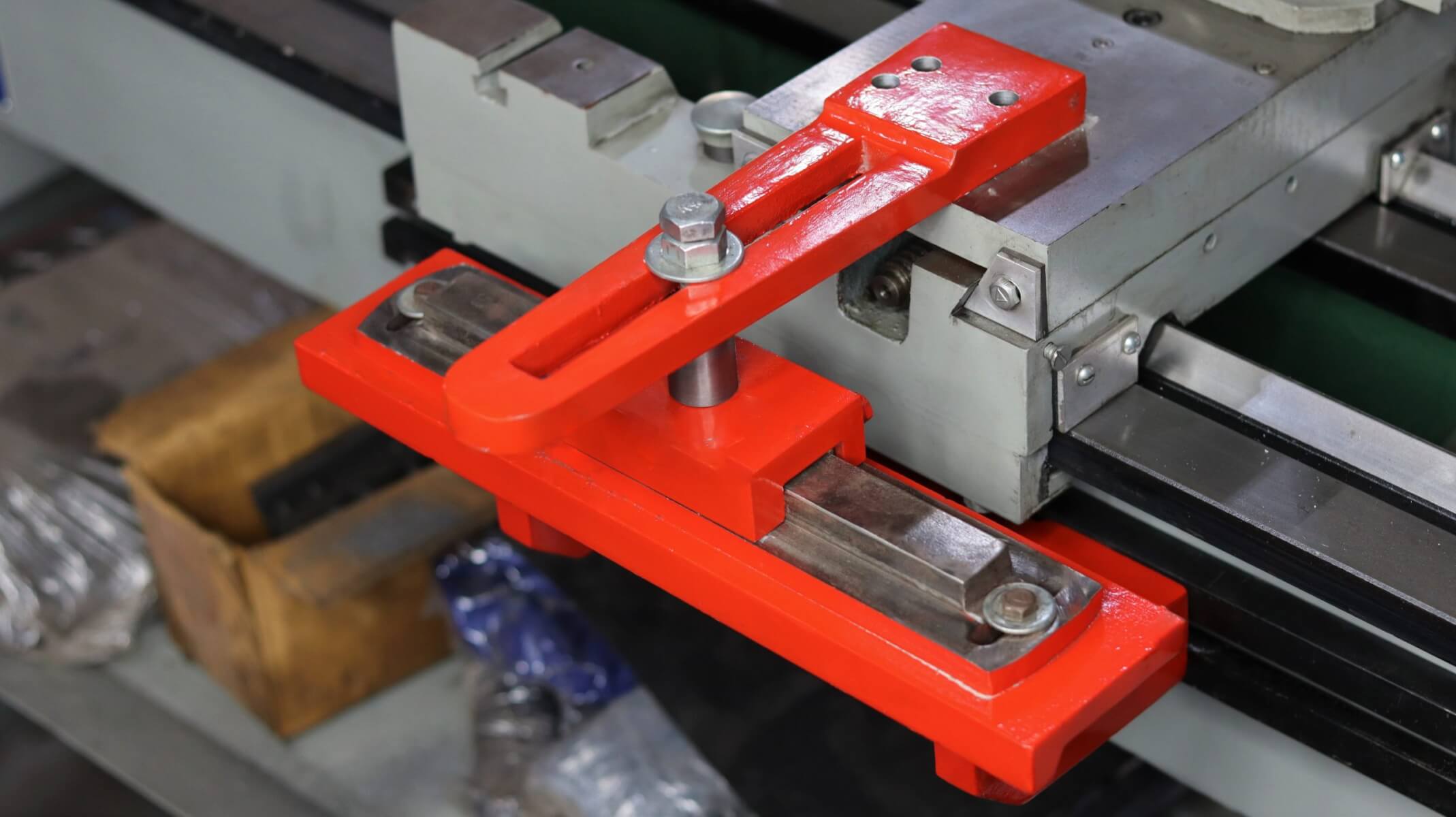

- Taper Turning Attachment is very much popular and fits all lathe machines.

- In ordinary straight turning, the cutting tool moves along a line parallel to the axis of the work, causing the finished job to be the same diameter throughout.

- When the diameter of a lathe workpiece changes uniformly, from one end to the other, the piece is said to be tapered.

- Taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part.

- Tapers can be either external or internal. If a workpiece is tapered on the outside, it has an external taper; if it is tapered on the inside, it has an internal taper.

Taper Turning Attachment Advantages:

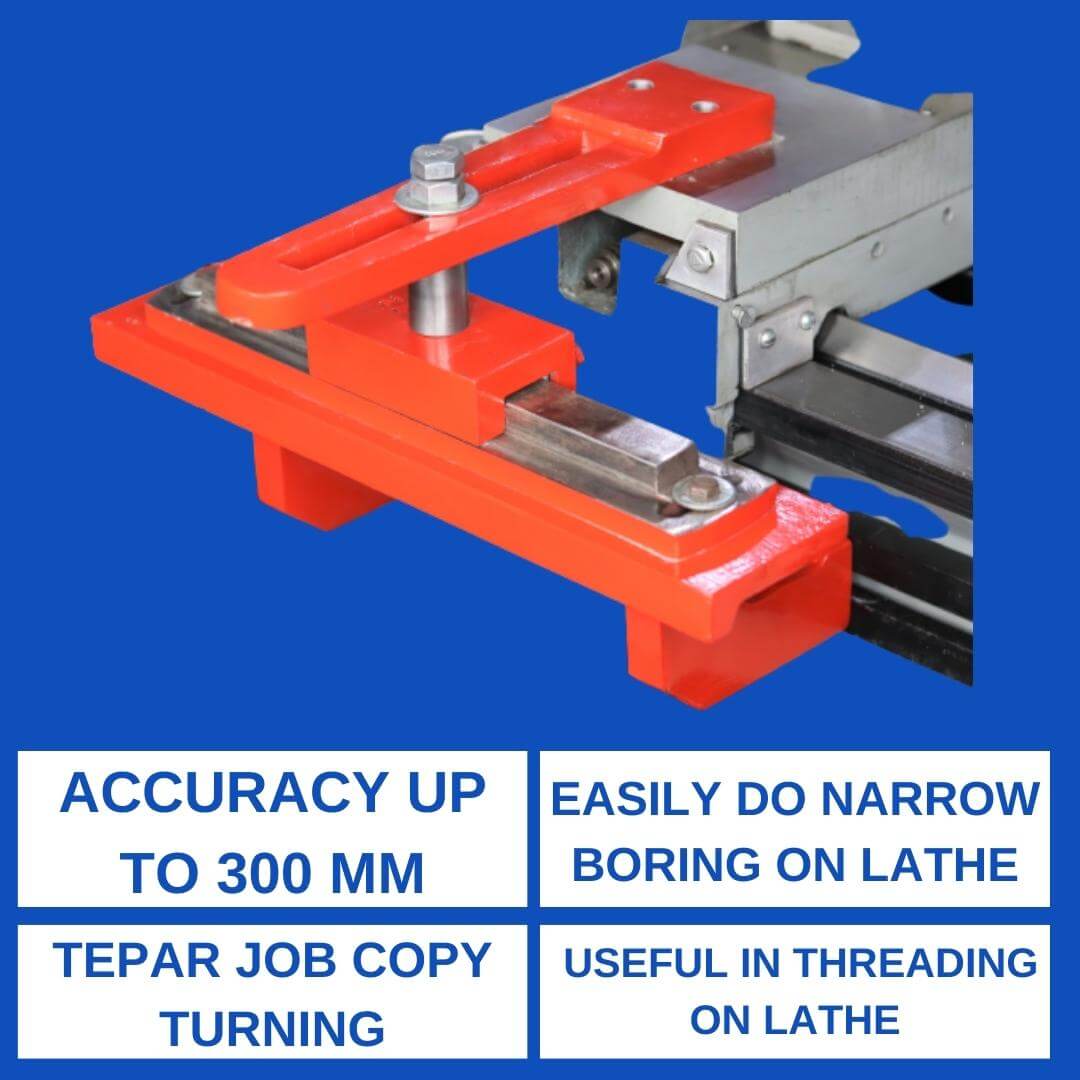

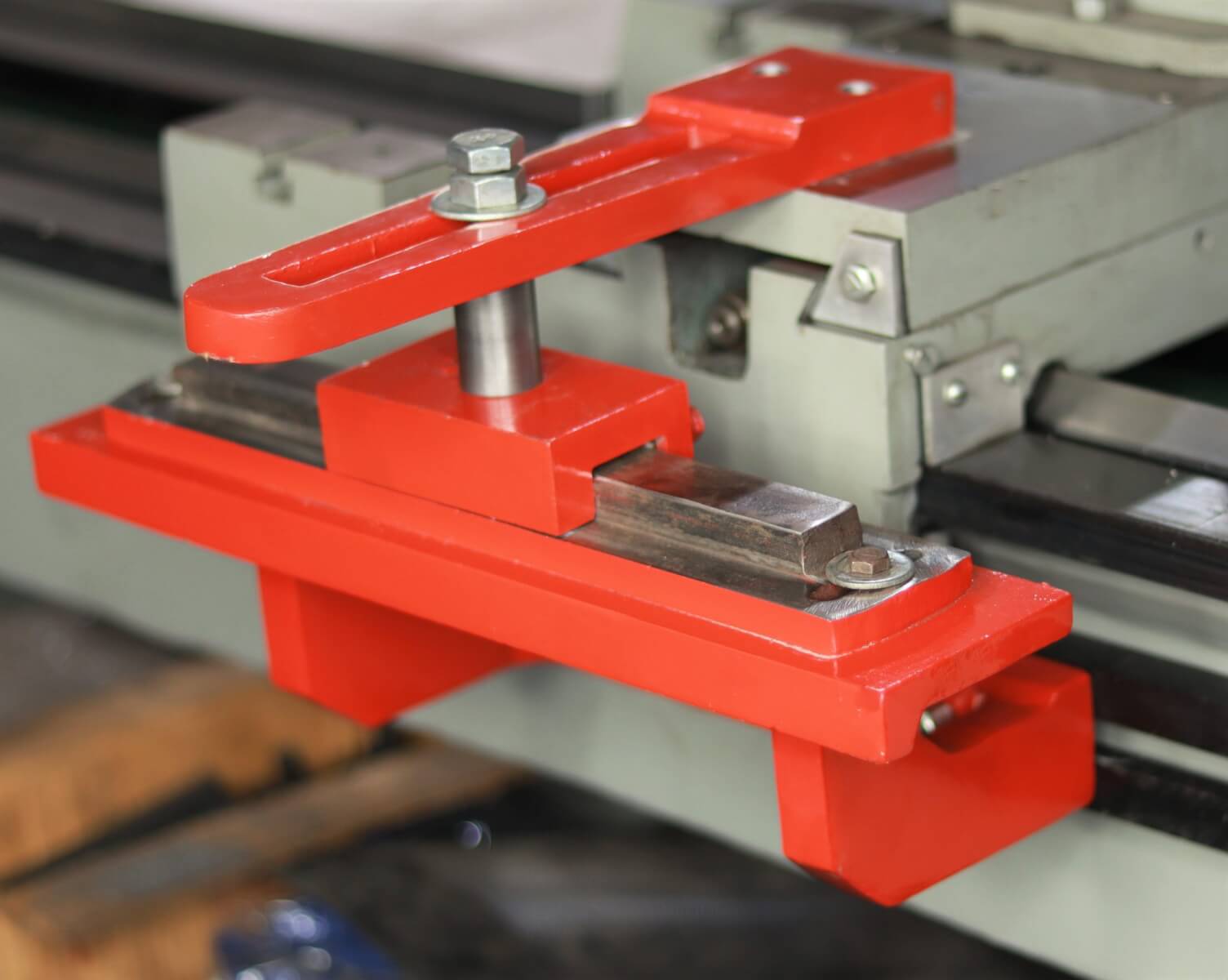

- Fast and consistent accuracy up to 300 mm Taper Turning job on the lathe.

- It’s useful in threading on the lathe workpiece inside as well as outside.

- Any length of the lathe workpiece can be tuned.

- At the set, the position accessory can be left.

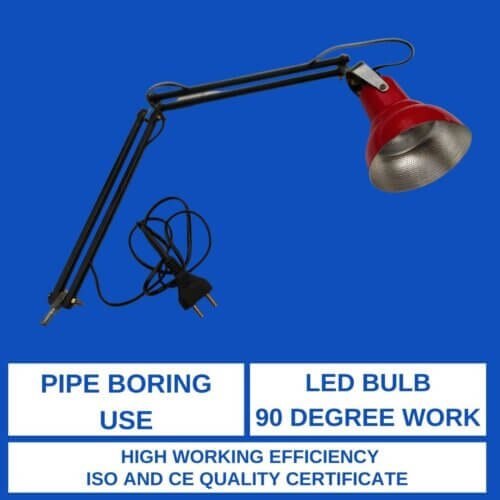

- With taper turning, we can easily do narrow boring on the lathe machine

Price :

| Accessory | Suitable Model | Price (Rs.) |

| Taper Turning Attachment [18 Kg] For Medium Lathe Machine | 34, 35, 40, 43 | 6500 |

| Taper Turning Attachment [30 Kg] For Heavy Lathe | 50, 60 | 7500 |

These are classified as follows :

- Morse Taper

- Used for drills, reamers, and lathe center shanks

- Brown & Sharpe Taper

- Used for taper shanks on tools (end mills, arbors, reamers, collets etc.) generally used on Brown and Sharpe machines

- Jarno Taper

- Used in lathe and drill spindles

- Standard taper pins (1/4 inch per foot)

- Used for positioning and holding parts together

More Production of Tapper Jobs:

- Consistent Accuracy up to 300 mm

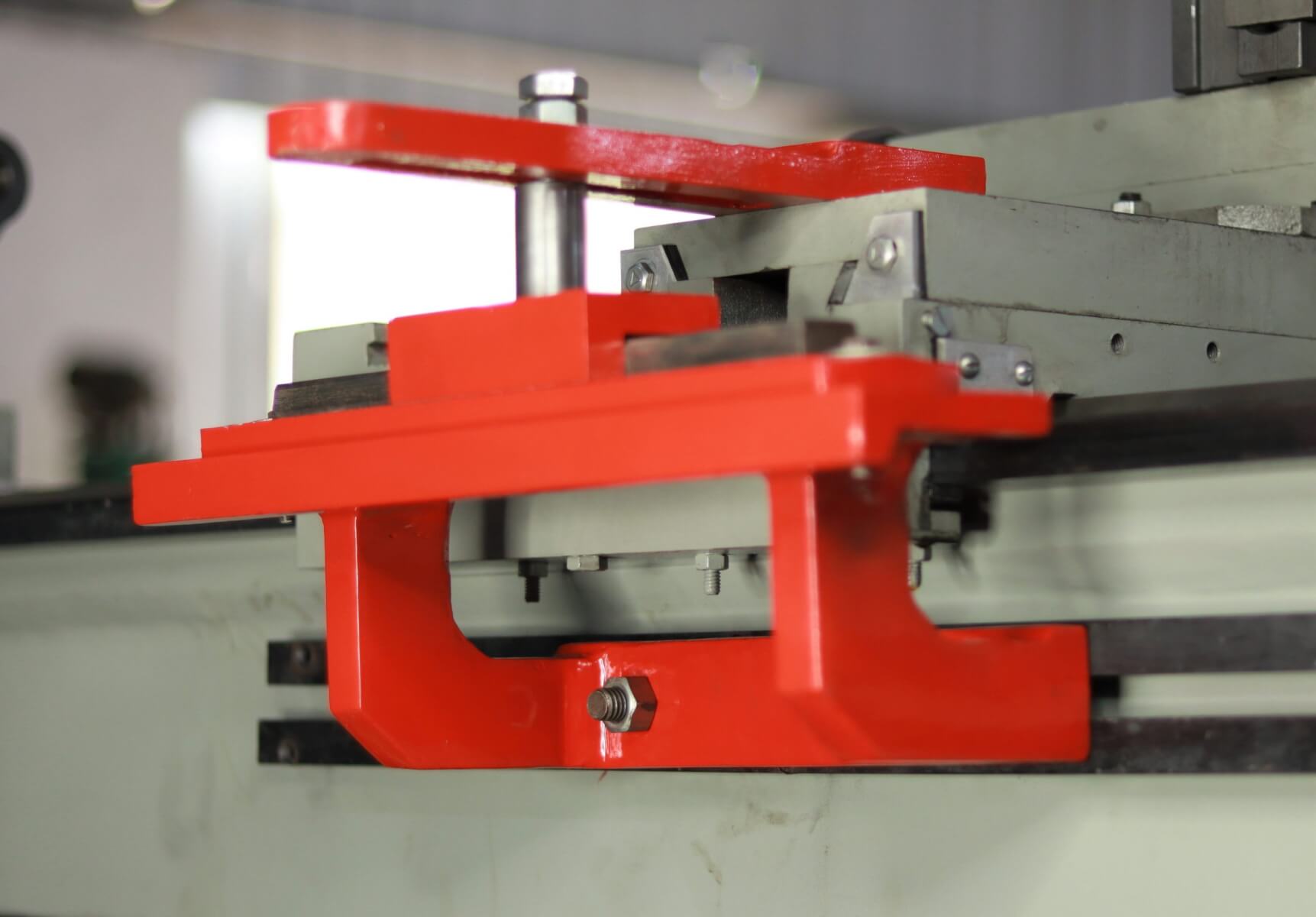

- Weight – 18kg

- Rust resistance

- Ruggedness

- Accurate dimensions

Taper Turning Attachment :

Taper Turning Attachment is very much popular and fits on all lathe machines. In ordinary straight turning, the cutting tool moves along a line parallel to the axis of the work, causing the finished job to be the same diameter throughout.

When the diameter of a piece changes uniformly, from one end to the other, the piece is said to be tapered. Taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. Tapers can be either external or internal. If a workpiece is tapered on the outside, it has an external taper; if it is tapered on the inside, it has an internal taper.

In Inch, system tapers are expressed in taper per foot, taper per inch, or degrees. While in the metric system is expressed as the ratio of 1 mm per unit of length.

Certain types of small tools and machine parts, such as twist drills, end mills, arbors, lathe centers, etc., are provided with taper shanks that fit into spindles or sockets of corresponding tapers, thus providing not only accurate alignment between the tool or other part and its supporting member but also more or less frictional resistance for driving the tool.

Tapers are classified by American Standards Association as self-holding tapers and steep or self-releasing tapers

Self-holding has been applied to the smaller tapers-like Morse and the Brown & Sharpe- because, where the angle of the taper is only 2 or 3 degrees, the shank of a tool is so firmly seated in its socket that there is considerable frictional resistance to any force tending to turn or rotate the tool relative to the socket. The term “self–holding” is used to distinguish relatively small tapers from the larger or self-releasing tapers.

We are here to help you

Q1:What is a Taper Turning Attachment?

A: Taper turning attachment is used to perform taper work over the shaft.

Q2:Which machine does the taper turning attachment fit into?

A: The taper turning attachment fits into the lathe machine.

Q3:In this taper turning attachment, how long can the job taper be?

A: With this taper turning attachment, you can taper a job up to 300 mm long.

Q4:What material is this taper turning attachment made of?

A: This taper turning attachment is made of cast iron material.

Q5:How to order this taper turning?

A: You can order this taper turning by phone or WhatsApp.

Q6:In how many days is the dispatch done after placing an order for taper turning?

A: After placing an order for taper turning, it is dispatched in a day or two.

Q7:Is the delivery charge extra for this taper turning?

A: This taper turning does not have to pay any separate delivery charge, you get free delivery to your address.

Q8:In how many days do we get taper turning?

A: You get taper turning in 5 to 7 days.

Q9:How to pack Taper Turning?

A: There is a packing of taper turning in the cartoon box, some parts are not broken in this way.