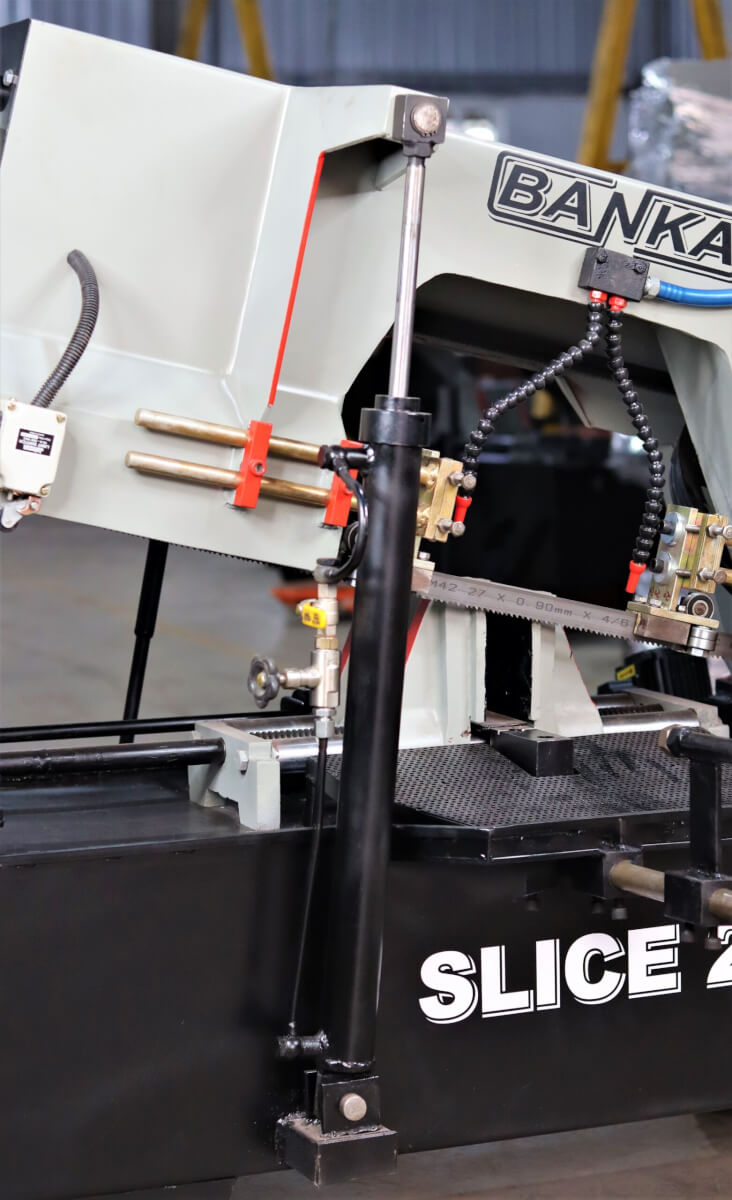

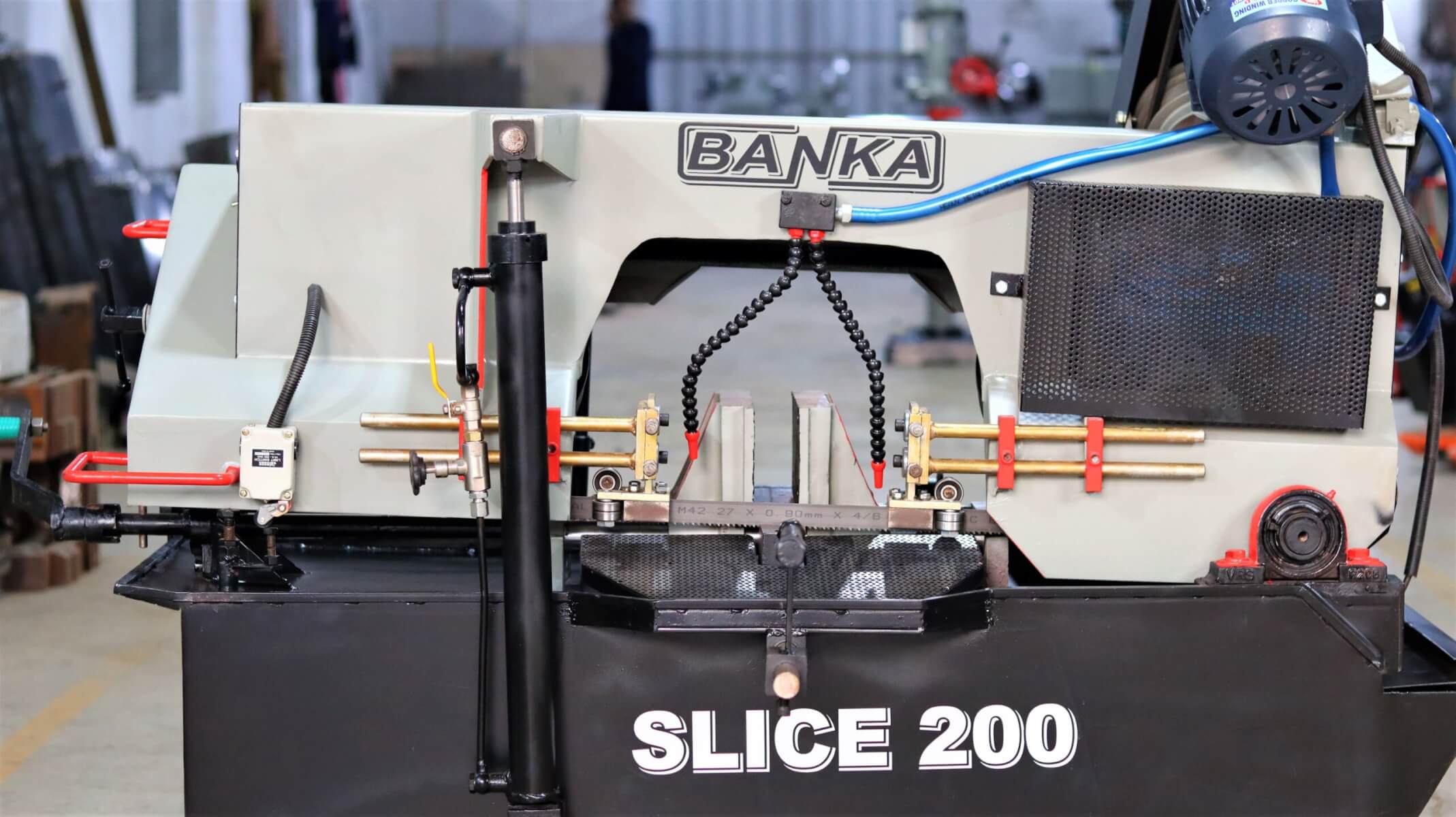

Bandsaw Cutting Machine (200mm) – Metal Cutting Machine – Pipe and Rod Cutting – High Speed Tube – Solid Steel – SLICE 200

₹1,39,000

- Model Type: Semi Hydraulic Metal Cutting Bandsaw Machine

- Category: Metal Cutting Machine / Workshop Machine

- Colour: Black & Grey Combo

- Cutting capacity: 200 mm

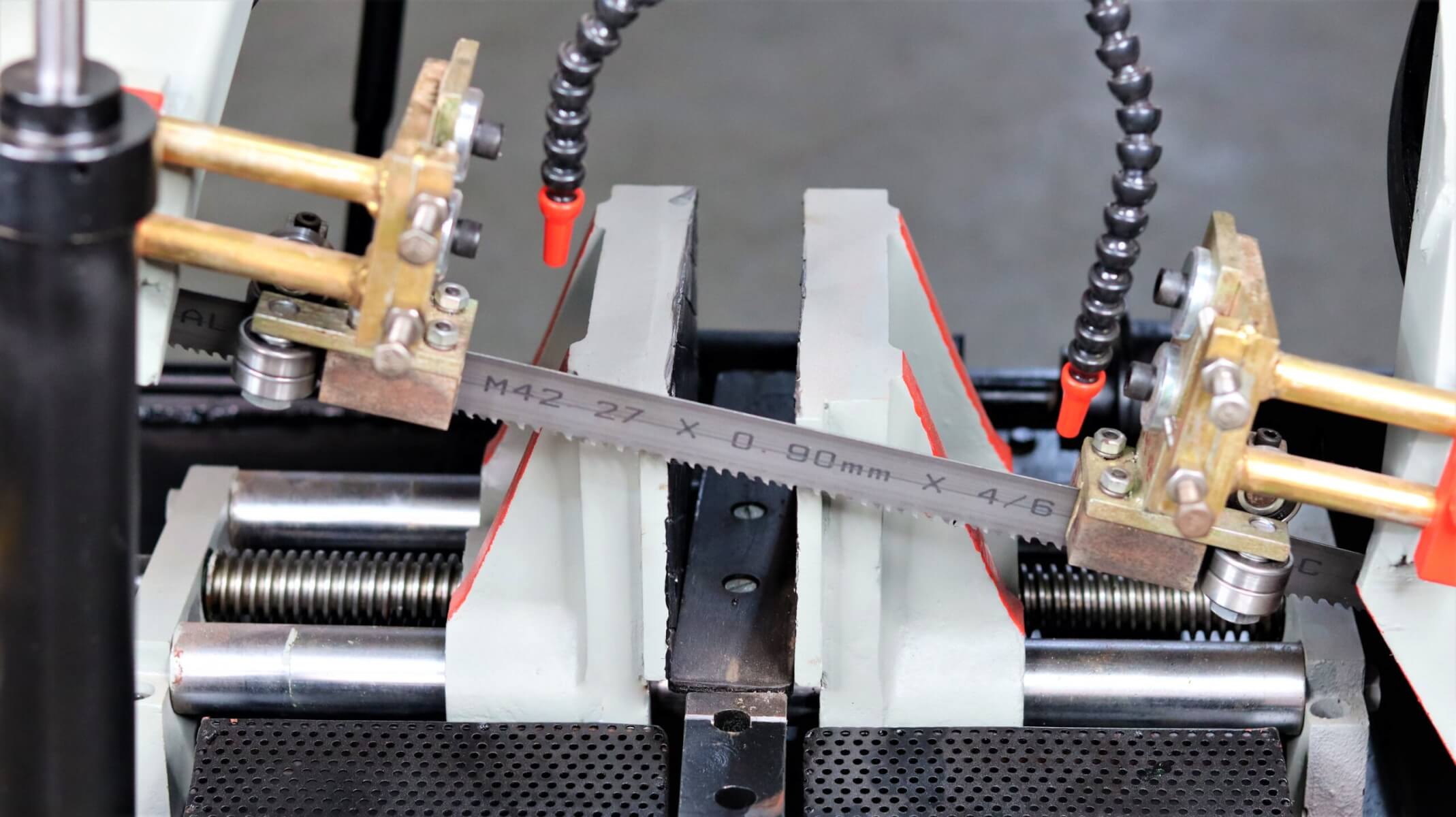

- Blade Size : 3000 x 27 x 0.9 (mm)

- Electricals: 1 HP

- Cutting Stroke Capacity: Round 200mm, Square 175 x 175, Casting, EN8, WPS Hard materials

Helps you to find your goal

| MODEL | BANKA SLICE 200 | |||||

| Round | MM | 200 | ||||

| Square | MM | 175 x 175 | ||||

| DRIVE | ||||||

| Drive Motor | 1 HP | |||||

| RPM | 1440/720 | |||||

| Coolant Pump | 0.15 H.P | |||||

| BLADE SPEED MTR/MINUTE | ||||||

| First | 10/20 | |||||

| Second | 18/35 | |||||

| Third | 28/55 | |||||

| BLADE SPECIFICATION | ||||||

| Blade size | MM | 3000 x 27 x 0.9 | ||||

| Floor space L x W x H | MM | 1600 x 700 x 1330 | ||||

| Job Holding Height | MM | 450 | ||||

Innovation with a Purpose

|

1) Coolant tank:

|

|

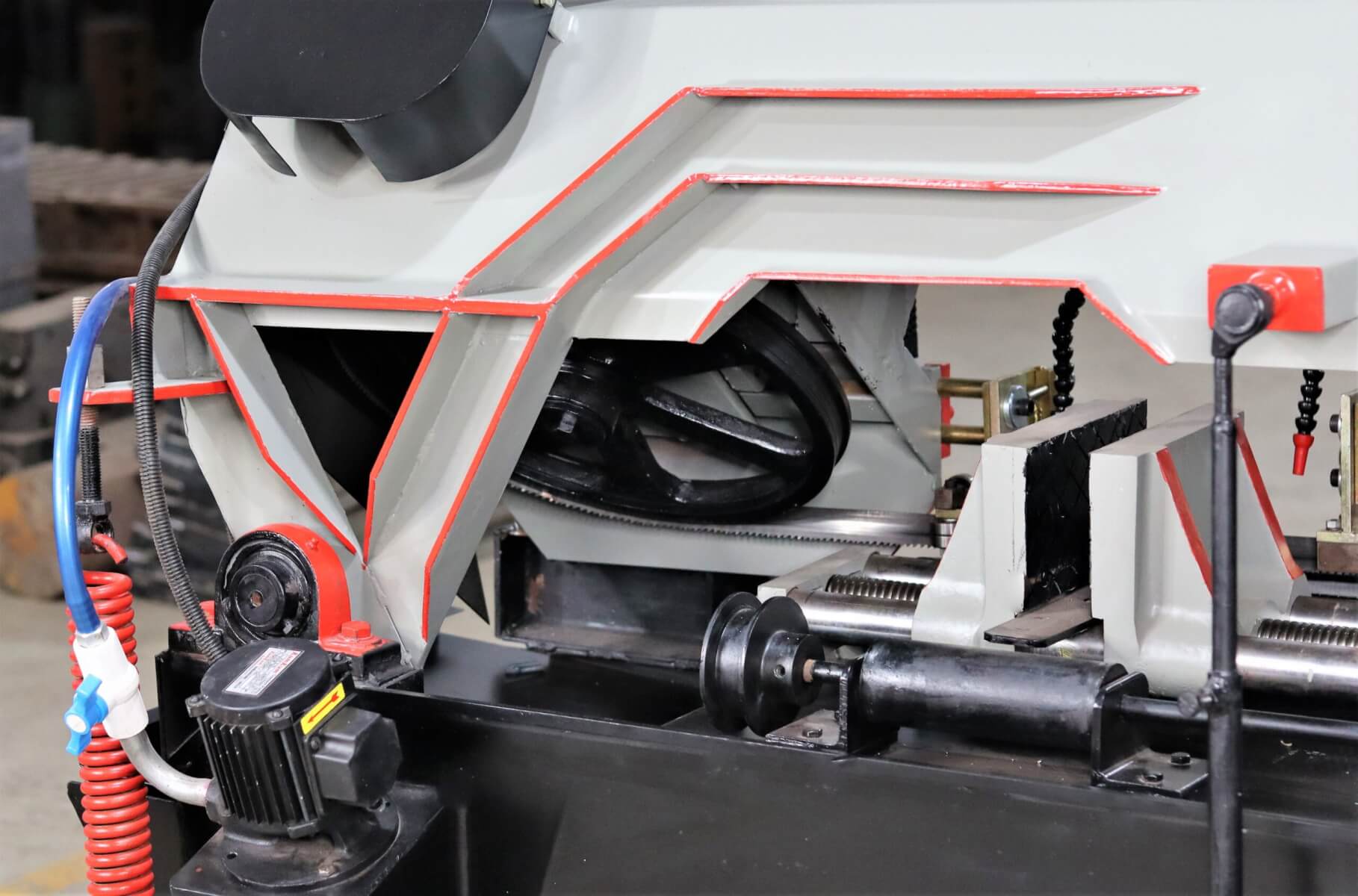

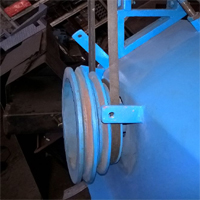

2) V-Grooved Use & 3-speed pulley:

Why is 3-speed pulley important?

|

|

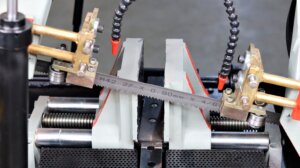

3) Limit Switch:

Auto stop:

|

|

4) Easy Foot Lifting:

|

|

5) Cover Box:

|

Lead us to serve more

Free Accessories:

– Complete with Electricals Saw Drive Electric Motor

– Coolant Pump

– On-Off Contactor with Push Buttons

– V – Belt Pulleys with V-Belt

– Job Stopper

– Oil Field Gearbox

We are here to Help you

1) What will be the warranty Period of this Bandsaw Machine?

A:Generally Suppliers of the Bandsaw machine are providing only one year warranty period in the Bandsaw machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service.

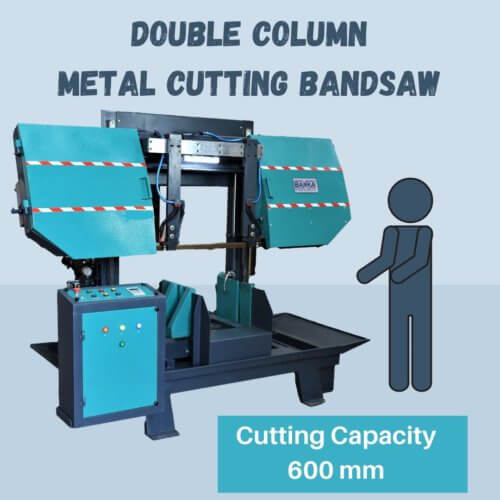

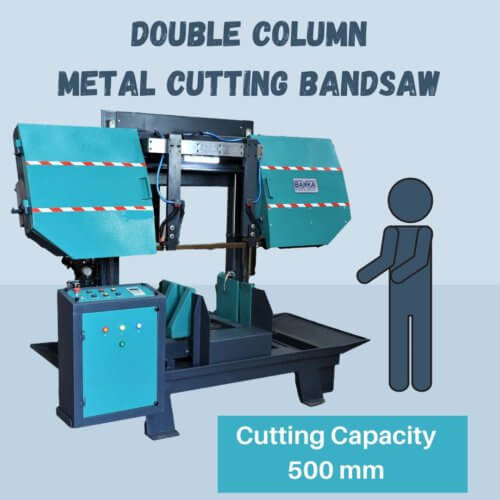

2) How Many types are available in Bandsaw Machine?

A:Generally there are mainly 3/4 types of Bandsaw machine are popular in the Market.

Manual Bandsaw Machine

Semi Automatic Bandsaw Machine

Single Column Bandsaw Machine

Double Column Bandsaw Machine

Fully Automatic Bandsaw Machine

3) What are the confusions raised in the mind of customer at the time of purchasing Bandsaw Machine ?

A :1) Cutting Capacity requirement

2) Light duty / Heavy Duty

3) Hydraulic OR Semi – Hydraulic

4) Single Column OR Double Column

4) Which Accessories I Should buy with the Hacksaw Machine?

A : Coolant Pump, Electric Motor, etc..

5) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.