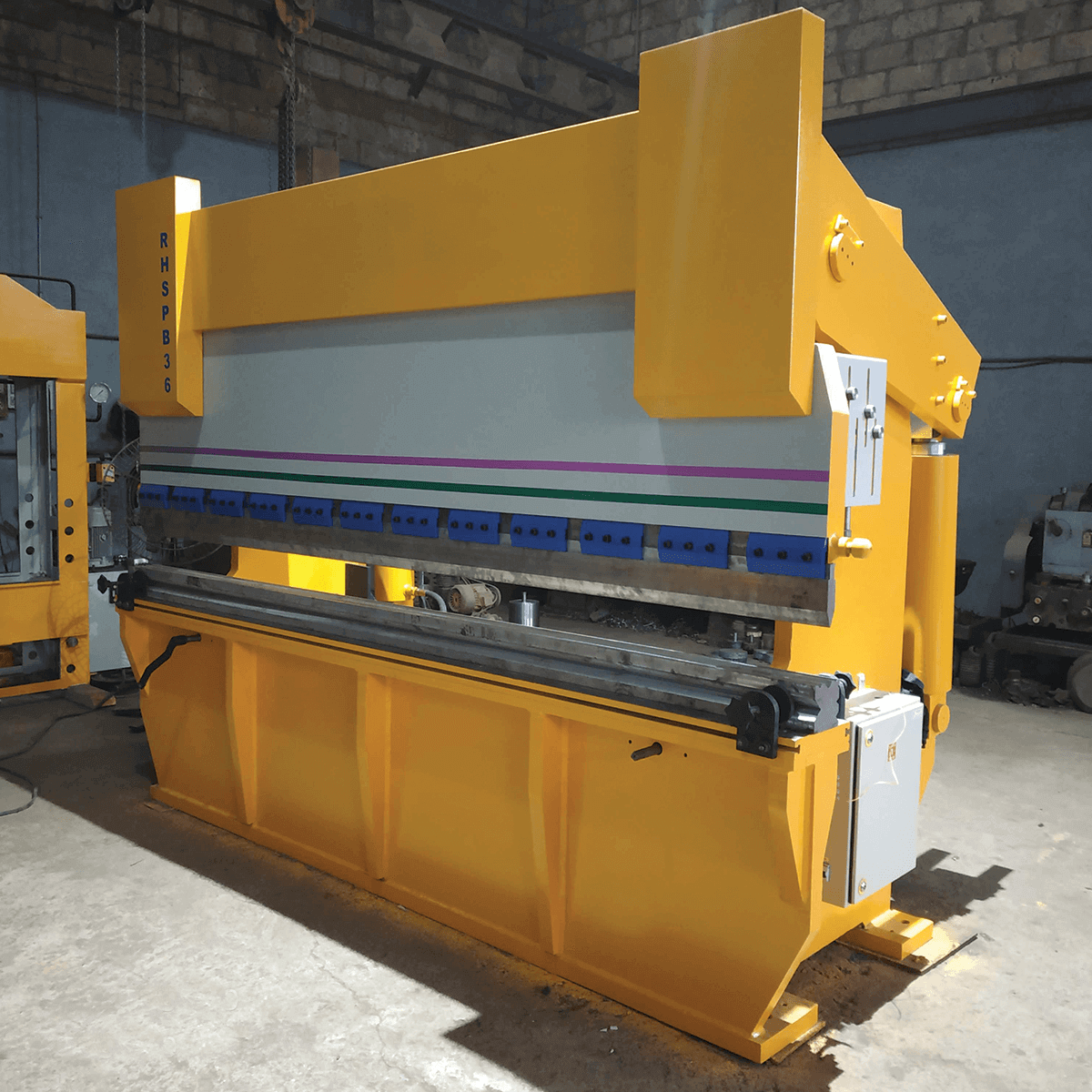

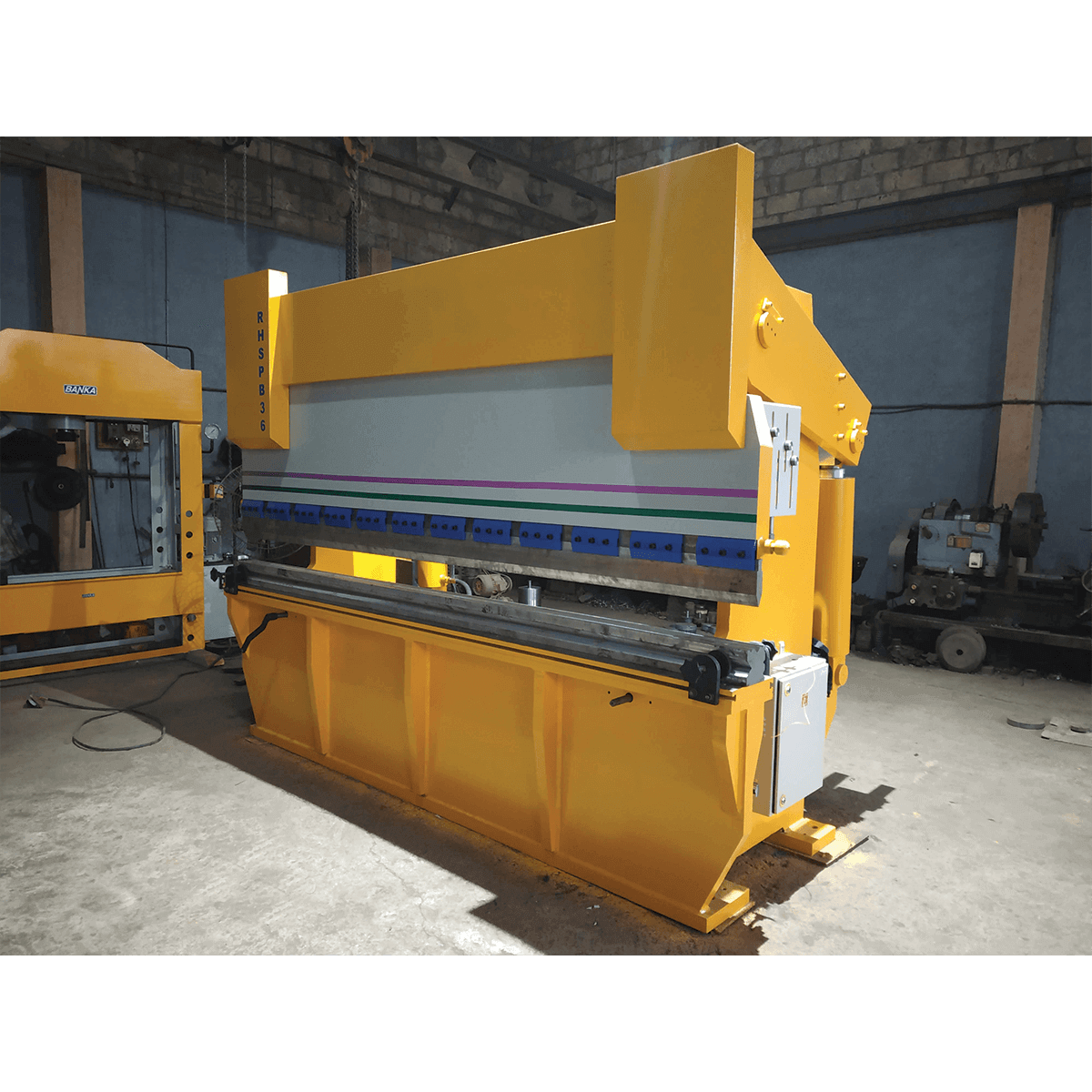

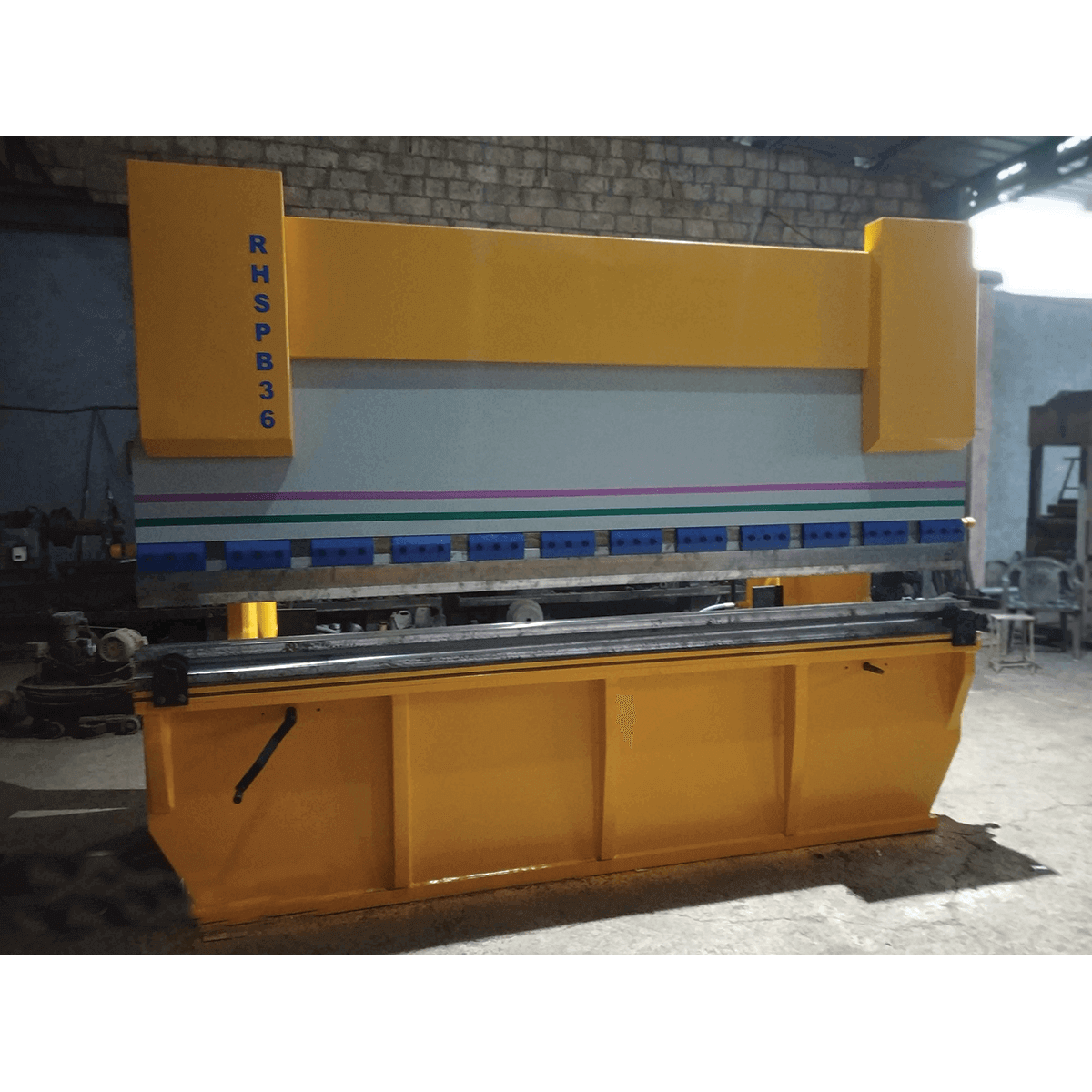

Hydraulic Press Brake Machine – Sheet Cutting – Sheet Metal Cutting – Maximum Tonnage 20 To 500 – Hydraulic Pressure Cutting – Bar And Plate Cutter

₹10,00,000

- Category : Workshop Machine / Cutting Machine

- Color : Saffron & White Combo

- Hydraulic Press Bending Capacity : 1.6 X 1500

- Motor : 2 hp

- Table With : 150mm

Separate us from others

RPB SERIES :

- Tonnage : 20 to 500M. Tons

- Length : 1500mm to 5000mm

- Press Brakes with NC Stroke : Y-axis

- NC Bachgauge : X-axis

Choice of Programmable Press Brakes NC Stroke (Y-axis) with LED Control :

- Multi-bend jobs easy with help of multiple front stops.

- Recalll popular stroke settings for different jobs.

- Bend sequence programmable with different stroks.

- Interrupt production conveniently for one-off jobs.

NC Stroke, NC Back Gauge (Y & X axis) with LCD Control :

- LCD control, menu, stores popular jobs-tools.

- Bends complex jobs quickly with minimal handling

- Accurate bends, Fewer inspections, rejections.

- Better productivity permits less machines-operators.

- Ecomomical against costlier multi-axes CNC brakes

- Faster set-ups, Part re-runs Exremely Fast.

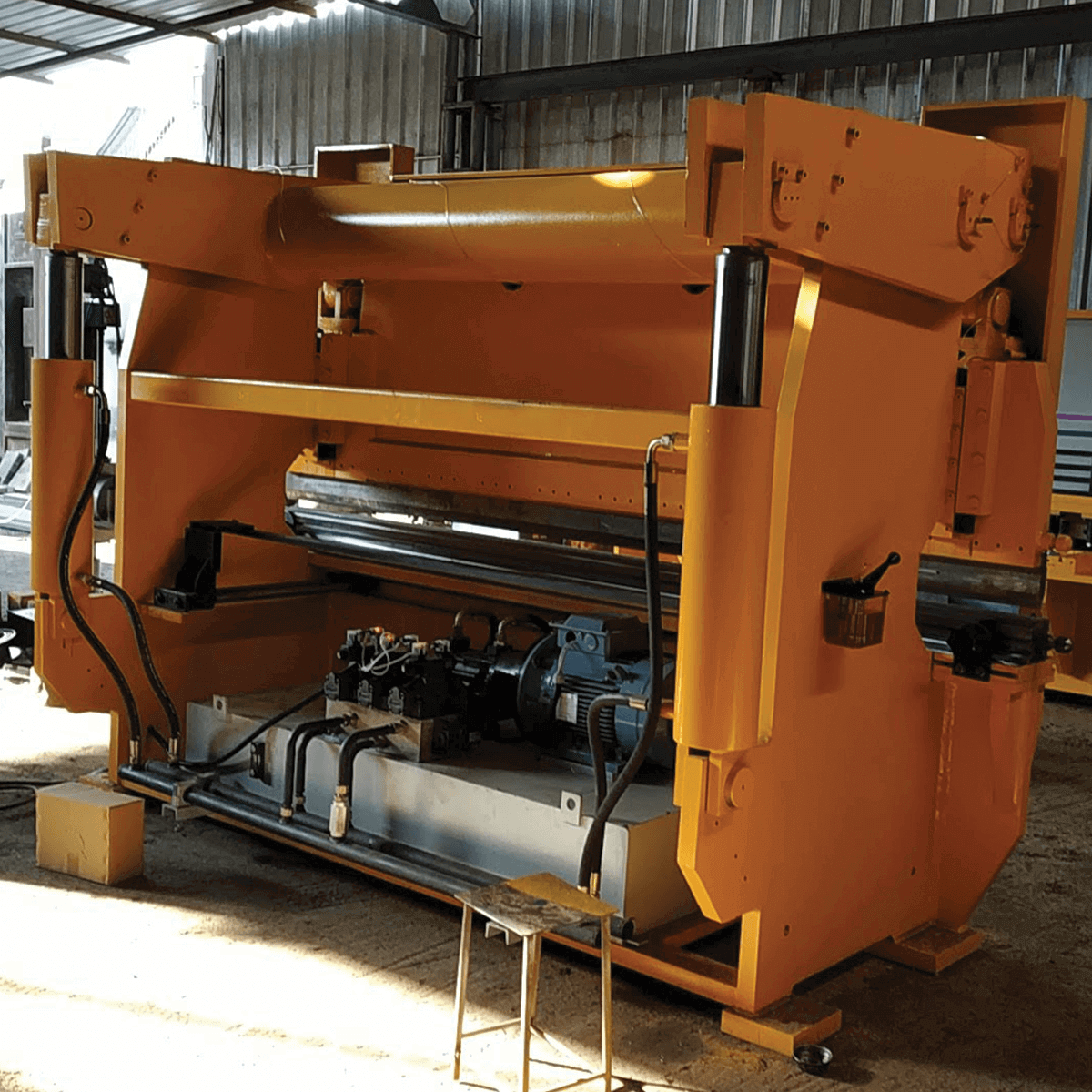

Rear Cylinder Drive and its Benefits :

- Two cylinders mounted on the rear drive the ram through levers.

- Torsion tube connects the levers to ensure parallel motion of ram.

- Levers multiply force, Simple cylinders, lower 160 bar working pressure.

- Smaller height-depth, hydraulic drive allows installing in tight places, upper floors.

Choice of Feature packed Press Brakes Basic model with SIngle Stroke Setting :

- Stroke referenced from bed, Repeatability ±0.03mm.

- Ram travel parallelism without use of servo-hydraulics.

- Convenient bend angle setting, 3-speed stroke cycle.

- Adjustable tonnage, Stroke length, speed change point.

- Front supports with stops-scale, set of back-stops.

Standard Features : Accessories for Basic Model

Ram travel repeatable within ±0.03mmfor consistent bends for interchangeable output. Ram travel is referenced from bed to aboid side frame deflections affecting stroke accuracy. Rugged structure from ultra tested IS 2062 grade B plates, rigidity conforming to international standards. Hydraulics, electrical fo internationally reputed brands for consistent performance and reliable opration. Front operated manual back gauge Front sheet supports with scale most hydraulic parts for 310 bar but working design with replaceable liners. Pivots with permanently lubricated bearings or hardened parts lubricated by central hand pump cylinders of ultra-tested seamless honed tubes, hard chrome-plated pistron, dual seals (Teflon ring plus set of chevron packing’s) for extra reliabilty. 3-speed bending cycles for faster output yet slow smooth bending with minimal shck loads. Movable control station with majority controls, emergency stop, up-down foot-switch controls. Inch cycle mode for set-up and one-off jobs. Single cycle modes for repeat cycle, production runs. Main cylinders seals can be easily replaced without requiring crane or dismantling the ram. Hydraulic power gives silent working, better safety against overload, instant stoppage-reversal of ram One set of unhanded standard punch, multi-vee die Block Lifting chains system and rotation of die block when using multi-vee die block.

Helps you to find your goal

| DEL | TONNAGE | TABLE LENGTH | HYDRAULIC PRESS BENDING CAPACITY (IN M.S. UTS 450KG./MM2 | TABLE WIDTH (MM) | CLEAR PASS MM | RAMS TROKE MM | OPEN HEIGHT MM | THROAT DEPTH MM | SPEED APPROACH PRESSING RETURN | SPEED APPROACH PRESSING RETURN | |

| RPB 214 | 20 | 1400 | 1.6 X 1500 | 2 X 1250 | 150 | 1060 | 100 | 250 | 100 | 35-9-35 | 2 |

| RPB 320 | 30 | 2100 | 2 x 2000 | 3 x 1250 | 150 | 1550 | 100 | 250 | 200 | 30-7-30 | 3 |

| RPB 425 | 40 | 2500 | 2 x 2500 | 3 x 1500 | 150 | 2055 | 100 | 250 | 200 | 40-8-40 | 3 |

| RPB 515 | 50 | 1500 | 4 X 1500 | 5 X 1250 | 190 | 1050 | 100 | 250 | 200 | 35-7-35 | 5 |

| RPB 520 | 50 | 2100 | 3 x 2000 | 4 x 1500 | 190 | 1550 | 100 | 250 | 200 | 35-7-35 | 5 |

| RPB 525 | 50 | 2500 | 2.5 x 2500 | 3 x 2000 | 190 | 2055 | 100 | 250 | 200 | 35-7-35 | 5 |

| RPB 625 | 65 | 2500 | 3 x 2500 | 4 x 2000 | 190 | 2055 | 150 | 330 | 200 | 30-5-30 | 5 |

| RHPB 630 | 65 | 3100 | 2.5 x 3000 | 3 x 2500 | 190 | 2540 | 150 | 330 | 200 | 30-5-30 | 5 |

| RHPB 825 | 80 | 2500 | 4 x 2500 | 5 x 2000 | 190 | 2055 | 150 | 330 | 200 | 38-6-45 | 7.5 |

| RPB 830 | 80 | 3100 | 3 x 3000 | 4 x 2500 | 190 | 2540 | 150 | 330 | 200 | 38-6-45 | 7.5 |

| RPB 1025 | 100 | 2500 | 5 x 2500 | 6 x 2000 | 190 | 2055 | 150 | 330 | 200 | 38-6-45 | 7.5 |

| RPB 1030 | 100 | 3100 | 4 x 3000 | 5 x 2500 | 190 | 2540 | 150 | 330 | 200 | 38-6-45 | 7.5 |

| RPB 1040 | 100 | 4100 | 3 x 4000 | 4 x 3000 | 190 | 3250 | 150 | 330 | 200 | 38-6-45 | 7.5 |

| RPB 1225 | 125 | 2500 | 6 x 2500 | 8 x 2000 | 250 | 2055 | 150 | 350 | 300 | 38-5-40 | 10 |

| RPB 1230 | 125 | 3100 | 5 x 3000 | 6 x 2500 | 250 | 2540 | 150 | 350 | 300 | 38-5-40 | 10 |

| RPB 1240 | 125 | 4100 | 4 x 4000 | 5 x 3000 | 250 | 3250 | 150 | 350 | 300 | 38-5-40 | 10 |

| RPB 1625 | 160 | 2500 | 8 x 2500 | 10 x 2000 | 230 | 2055 | 150 | 350 | 300 | 35-6-40 | 15 |

| RPB 1630 | 160 | 3100 | 6 x 3000 | 8 x 2500 | 230 | 2540 | 150 | 350 | 300 | 35-6-40 | 15 |

| RPB 1640 | 160 | 4100 | 5 x 4000 | 6 x 3000 | 230 | 3100 | 150 | 350 | 300 | 35-6-40 | 15 |

| RPB 2030 | 200 | 3100 | 8 x 3000 | 10 x 2500 | 230 | 2540 | 200 | 400 | 300 | 35-7-45 | 20 |

| RPB 2040 | 200 | 4100 | 6 x 4000 | 8 x 3000 | 230 | 3100 | 200 | 400 | 300 | 35-7-45 | 20 |

| RPB 2050 | 200 | 5100 | 5 X 5000 | 6 X 4000 | 230 | 4100 | 200 | 400 | 300 | 35-7-45 | 25 |

| RPB 2530 | 250 | 3000 | 10 x 3000 | 12 x 2500 | 300 | 2540 | 200 | 400 | 300 | 35-6-40 | 25 |

| RPB 2540 | 250 | 4000 | 8 x 4000 | 10 x 3000 | 300 | 3100 | 200 | 400 | 300 | 35-6-40 | 25 |

| RPB 3030 | 300 | 3000 | 12 x 3000 | 15 x 2500 | 300 | 2540 | 200 | 400 | 300 | 30-6-35 | 30 |

| RPB 3040 | 300 | 4000 | 10 x 4000 | 12 x 3000 | 300 | 3100 | 200 | 400 | 300 | 30-6-35 | 30 |

| RPB 4030 | 400 | 3000 | 16 x 3000 | 20 X 2500 | 300 | 2540 | 250 | 500 | 350 | 30-6-35 | 40 |

| RPB 4040 | 400 | 4000 | 12 x 4000 | 16 x 3000 | 300 | 3100 | 250 | 500 | 350 | 30-6-35 | 40 |

| RPB 4050 | 400 | 5100 | 10 X 5000 | 12 X 4000 | 300 | 4100 | 250 | 500 | 350 | 25-5-40 | 40 |

| RPB 5030 | 500 | 3100 | 20 X 3000 | 25 X 2500 | 300 | 2550 | 250 | 500 | 350 | 25-5-40 | 50 |

| RPB 5040 | 500 | 4100 | 12 X 4000 | 20 X 3000 | 300 | 3100 | 250 | 500 | 350 | 25-5-40 | 50 |

| RPB 5050 | 500 | 5100 | 12 X 5000 | 15 X 4000 | 300 | 4100 | 250 | 500 | 350 | 25-5-40 | 50 |

Innovation with a Purpose

BANKA Machines have been playing a crucial role in bringing the revolution for manufacturing industrial machines. Not only from the recent past but since decades started from 1977, we have concentrated on defining a whole new horizon in manufacturing, supplying and trading of Industrial Machines. BANKA Machines shares this feat with its customers rendering our first-rate products and services.

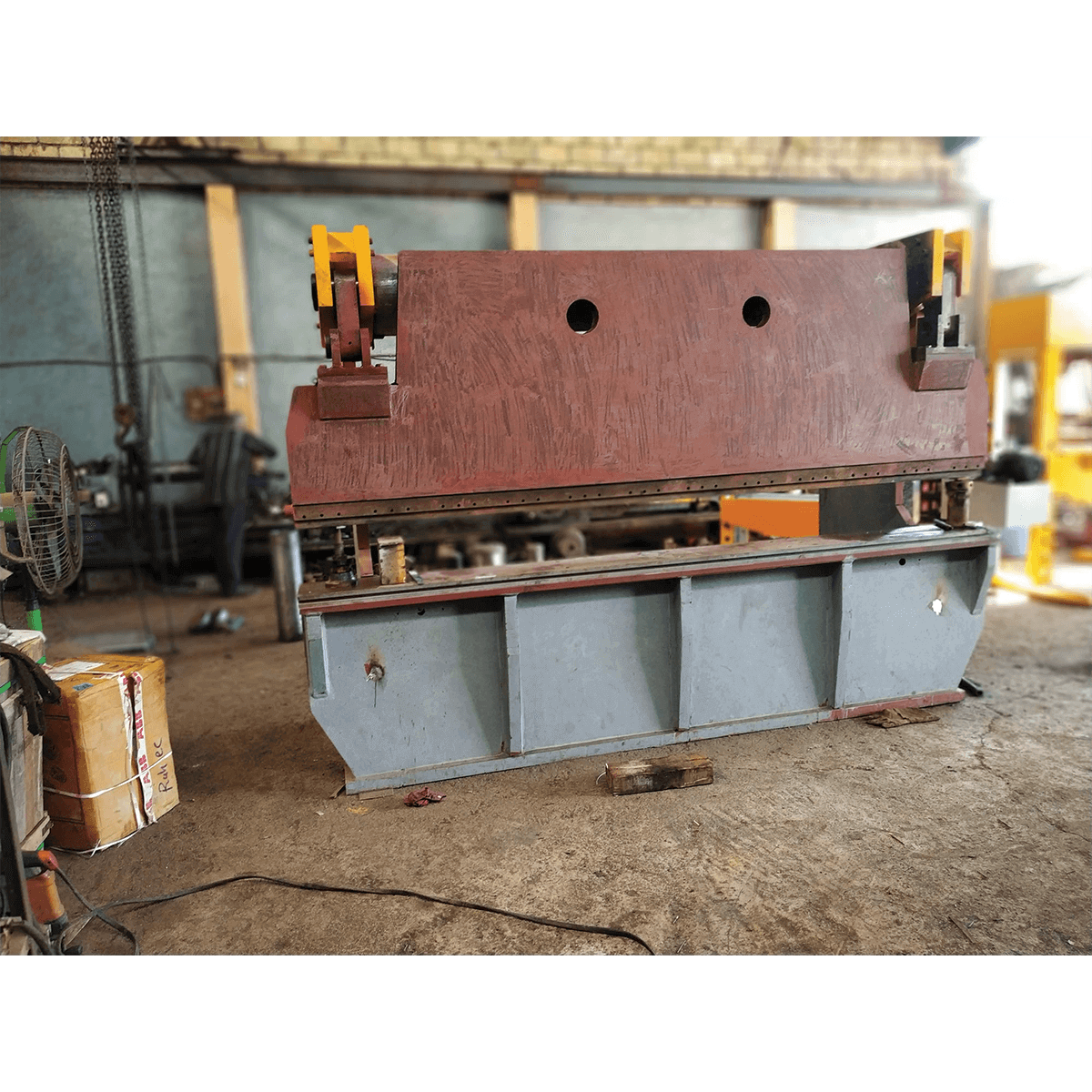

A Press Brake Machine is generally used for bending or moulding metal sheets in order to shape it as per encoding by clamping the sheet between exertions and die. A Press Brake Machine is also known as Brake Press.

BANKA’s Hydraulic Press Brake Machine is a resultant display of our experienced R & D team and industrious approach for making customized customer-oriented and operator-friendly machines. This machine can be operated for multiple tasks at a time. The feature of programmable bend sequence helps easy and fast operations.

The automated system with high rigidity value sets International Standards. The cylinders are mounted on the back side of Press Back and synchronize ram and table in parallel inducing mechanical links connected with the cylinder.

BANKA’s Hydraulic Press Brake Machine has automated system requiring less manpower and hence reduced labour overheads.

This is the cost-effective machine as hydraulic system ensures more operations leading to mass production and low cost per operation.

We are here to Help you

1) What will be the warranty Period of this Press Machine?

A: Generally Suppliers of the lathe machine are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service.

2) How Many types are available in Press Machine?

A: 1) Hydraulic Press Machine

2) Power Press Machine

3) What are the models available in the Hydraulic press machine?

A :

Hydraulic press machine 5 ton capacity

Hydraulic press machine 15 ton capacity

Hydraulic press machine 25 ton capacity

Hydraulic press machine 40 ton capacity

Hydraulic press machine 60 ton capacity

Hydraulic press machine 75 ton capacity

Hydraulic press machine 100 ton capacity

4) What type of oil should I use in my Hydraulic Press Machine?

A: 68 Grade Oil

5) How much oil is used in my Hydraulic Press Machine?

A: 50 ltr.

6) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally, our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.