Accessories for Lathe machines, Machine Shop Accessories, Tools & Instruments

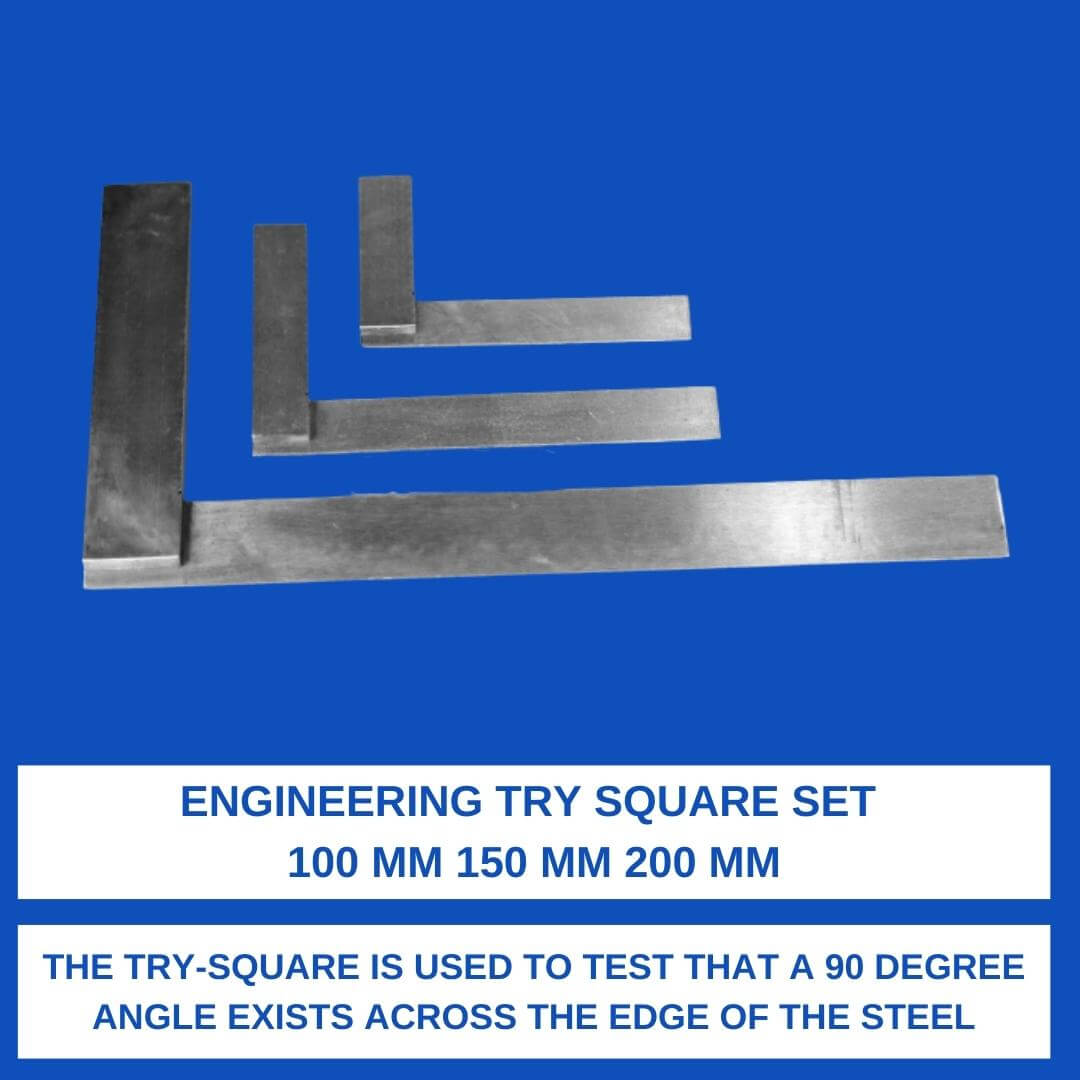

Try Square Set

Tag: Popular

₹2,300 ₹2,000

The simplest method of checking a low grade square for accuracy is to draw a line across a board with a flat face and straight edge. Then flip the square over 180 degrees and check if the blade aligns with the line just drawn. Any error is multiplied by two and appears as a wedge or taper In the example seen opposite, the try-square is used to test that a 90 degree angle exists across the edge of the steel. Although a burr exists on the edge of the steel it fits into the slot and does not affect the way the try-square is used.

Weight: 0.81 Kg

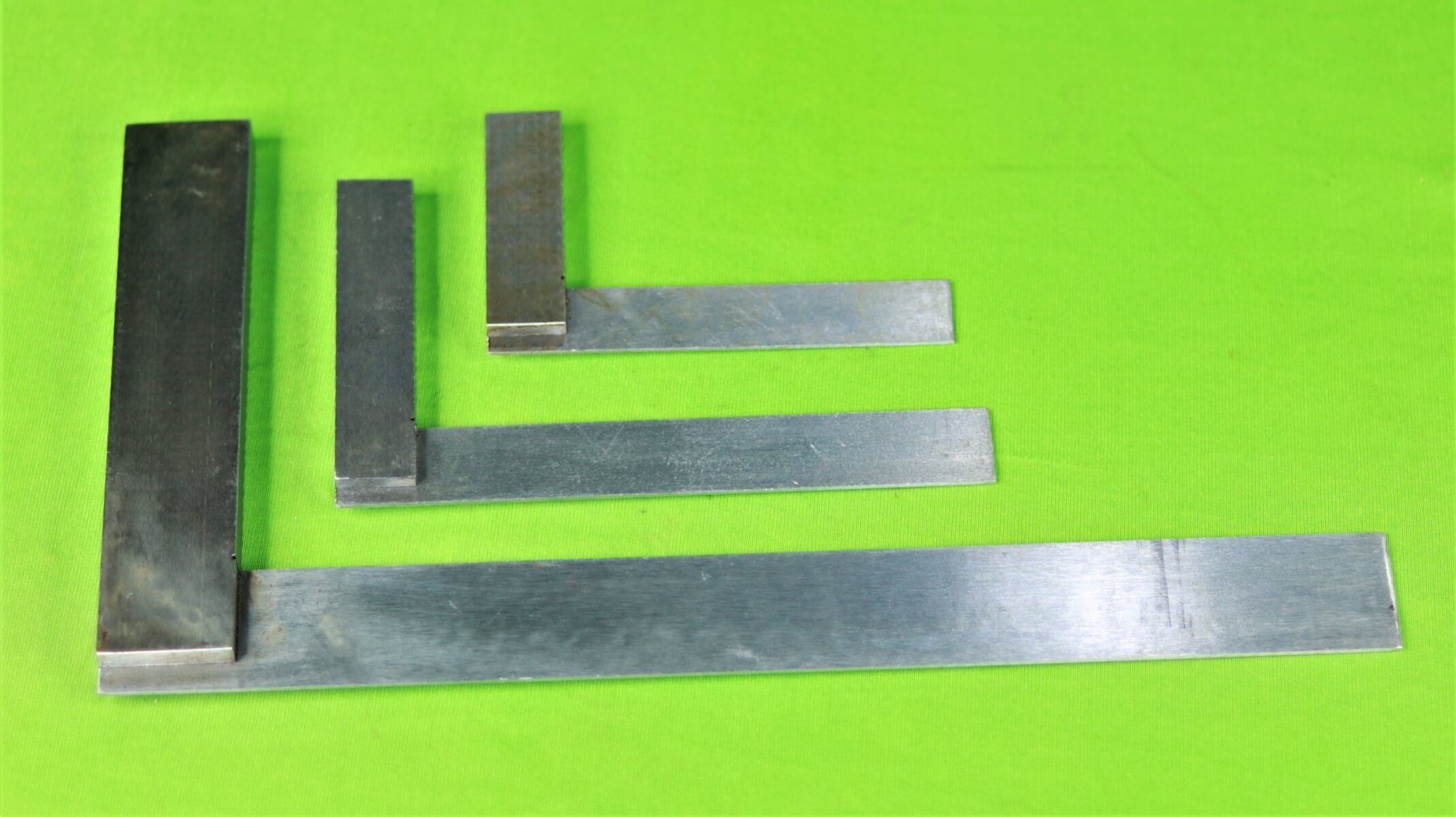

- The engineer’s try-square is composed of two parts, the stock and the blade. They are usually made from bright mild steel with the blade being hardened and tempered so that it resists damage. It is normally used during engineering / metalworking projects

- A typical use of an engineer’s try-square is to mark out material for cutting/shaping.

- The try square is pushed against a straight side of the material (eg. steel). An engineer’s scriber is then used to scratch a line onto the surface of the metal. Sometimes engineers blue (a dye/ink) is wiped onto the surface first so that the scratched line can be seen easily. The material is then cut down to this straight line.

- Look closely at an engineer’s try-square, you should see an interesting feature. There should be a small slot that has been cut into the stock. This prevents small burrs caused by filing from altering the try-squares accuracy. Dirt can also collect on metal surfaces, again the slot helps prevent measuring angles inaccurately.

- Solid steel engineers square with hardened, tempered and finely polished blades. Different sizes of Engineers’ squares feature:✔ Unbelievable value for money. Product Description: Top quality Engineer…

- The simplest method of checking a low grade square for accuracy is to draw a line across a board with a flat face and straight edge. Then flip the square over 180 degrees and check if the blade aligns with the line just drawn. Any error is multiplied by two and appears as a wedge or taper

- In the example seen opposite, the try-square is used to test that a 90 degree angle exists across the edge of the steel. Although a burr exists on the edge of the steel it fits into the slot and does not affect the way the try-square is used.

- Engineering Try Square set 100 mm 150 mm 200 mm

- Engineering Try Square Sizes

- – 100 mm / 4″ inch

- – 150 mm / 6″ inch

- – 200mm / 8″ inch