टूल ब्रेज़िंग का ज़माना तो गया, इनके बदले इंसर्ट टूल सस्ता पड्ता है। Brazen Tool vs end mill Tool Holder

We supply Cheap and economical tools for Lathe from Rajkot to all over India. Buy Lathe Tools from us and with no shipping charges.

हम पूरे भारत में राजकोट से खराद के लिए सस्ते और किफायती उपकरण की आपूर्ति करते हैं। खराद उपकरण हमसे खरीदें और बिना किसी शिपिंग शुल्क के।

Why should we not use brazen tools?

हमें ब्रेजिंग टूल्स का उपयोग क्यों नहीं करना चाहिए?

Know more about Carbide Tool Tips and the brazing process I mean Brazing Process for lathe tools. Should we use brazed tip tooling or not? Get carbide tools for lathe and CNC at the best price in India. We also sell Brazed Tools at the Best Price in India.

Tool holders: We are a Tool Holder Manufacturer from Gujarat who gives our customers a 100% return policy.

Tool Holder Wholesale Trader also buys from us. We sell CNC external tool holder clamps, and End Mill holders too.

What are the tools used in a lathe? खराद में प्रयुक्त उपकरण क्या हैं?

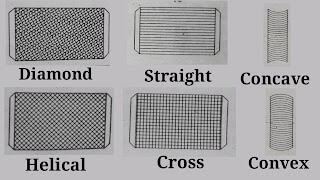

नर्लिंग टूल के प्रकार (Types of Knurling Tools)

- डायमंड नर्लिंग टूल (Diamond Knurling Tool)

- सीधा / स्ट्रेट नर्लिंग टूल (Straight Knurling Tool)

- क्रॉस नर्लिंग टूल (Cross Knurling Tool)

- तिरछा / हेलीकल नर्लिंग टूल (Helical Knurling) Tool

- अवतल / काॅनकेव नर्लिंग टूल (Concave Knurling Tool)

- उतल / कॉन्वेक्स नर्लिंग टूल (Convex Knurling Tool)

Where is a single point tool used? सिंगल पॉइंट टूल कहां यूज़ होता है?

A single-point cutting tool is widely used in metal cutting industries for forming the required shape. It is used on lathe and shaper machining for performing operations like turning, facing, chamfering, boring shaping, etc. This cutting tool has a single cutting point that cuts the workpiece by rubbing over it.

How does an insert fit into a tool holder?

टूल होल्डर में इन्सर्ट कैसे फिट होती है?

A tool holder is a machining component that holds the end mill in place. Its purpose is to hold the tool in place as precisely and firmly as possible, as a barely perceptible increase in runout can ruin your project or break your cutting tool.

- Select insert geometry based on selected operation, for example, finishing.

- Select the largest possible nose angle on the insert for strength and economy.

- Select the insert size depending on the depth of cut.

- Select the largest possible nose radius for insert strength.

- Select a smaller nose radius if there is a tendency for vibration.

- Lathe Machine Manufacturer.

How often will insert be used in the tool holder?

टूल होल्डर में इंसर्ट का उपयोग कितनी बार होगा?

We often use an insert in the tool holder. It is designed for finished cutting, to give a smooth surface on the surface being cut. It uses special geometry to give a good finish on the workpiece at a higher-than-normal feed rate.

Why does the brazing tool have a short life?

ब्रेज़िंग टूल की लाइफ क्यों कम होती है?

- Producing lower strength joints compared to welding.

- Producing joints that are not as well suited to high-temperature applications as welds.

- Fluxes may contain toxic components.

What is the use of the knurling tool?

नरलिंग टूल का उपयोग क्या होता है?

A knurling tool is a manufacturing and repairing tool used on lathe machines. A knurling tool is used to give the metal a criss-cross pattern shape, which helps the human hand to hold the knurled tool more firmly.